Why ALLEYE CMMS

- kiakahhali

- Jun 18, 2022

- 1 min read

What you may not know is that in an average size laboratory or production facility, you can easily find between 100 to 300 pieces of equipment or instrument that require preventive maintenance, qualification and/ or calibration in order to stay compliant and fit to support testing or production activities.

Managing and keeping track of the maintenance or metrology department activities even on a small scale is a laborious, time-consuming and complex task that ALLEYE CMMS makes you perform faster, more accurately and more economical.

Open each tab to get a taste of the numbers.

Fast

85.5% FASTER DEPLOYMENT:

From scratch validation conception 4 months vs CSV package 2 weeks.

Execution of 100 tests and document it manually (5 per day) 1 month vs 300 Automated test execution and documentation in 4 hours.

From To

5 months 14.5 days

See for yourself: executing 3 test scripts and generating video in less than a minute

100% FASTER REPORTING

Calculating KPI (like downtime, backlog, load and capacity of the maintenance team, individual and team performance) on a periodic or on-demand will take an average of 1-day per report which translates easily between 12 to 15 days per year vs the instantly available reports.

Gathering information for root cause analysis of an investigation within the scope of a major instrument category 2 days vs searching and querying ALLEYE DB takes less than 30 minutes.

17 days 30 min

Accurate

100% more informed decisions

From guesswork to data-driven, how do you respond to this kind of question?

What equipment is the best candidate to be replaced in the next budget?

Guesswork: Based on employee or team perception, or date of purchase.

Data-driven: Equipment downtime trend, and maintenance cost trend

Do you need more resources in the coming year? How do you justify it?

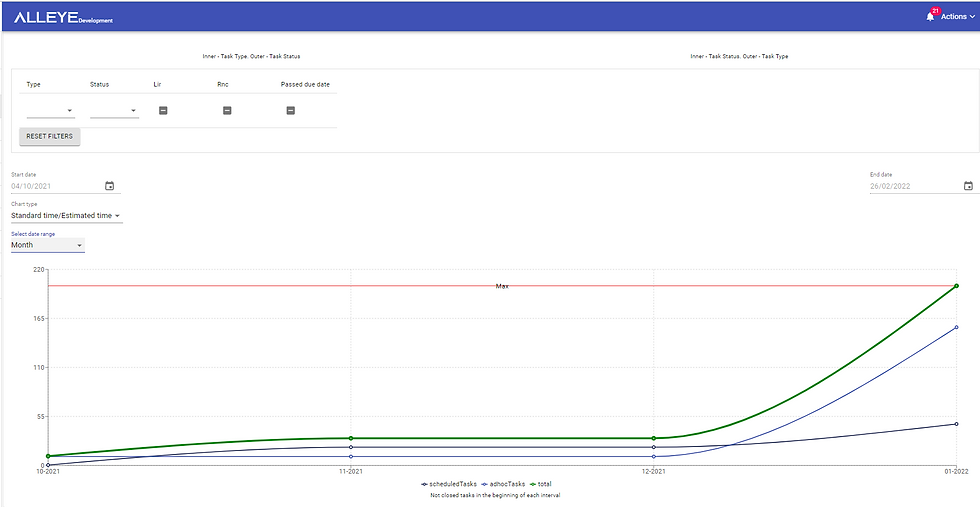

Guesswork: Based on approximate workload and capacity of the team today or past experience.

Data-driven: based on exact capacity and load projection and backlog trends including the scheduled tasks and ad-hoc demands.

Guesswork Data driven

Economical

Over 55% economy in deployment CAPEX

Traditional deployment and validation capital expenses of similar software in GxP environment is almost 3 to 5 times the purchase cost, which in an average study case comes to about 60K$ vs the cost of our validation package and 300 automated tests for 15K$.

Less running cost equal to 1 person/two years

Average saving of reporting efforts/year (15d x 1 person)

Average saving on unnecessary and unorganized communication (30 min daily 3 people + 30min weakly 20 people which comes to 910h/year)

Average saving on investigation costs for 5 investigations per year (10 days 1 person)

Minimum economy of 1 person every two years

Explore for more, from stress to confidence

The case studies above were just to give you a taste of some benefits that are easier to calculate. and there are many other benefits that we would like to explore with you at no cost such as

The economy in reducing non-added value movements.

Confort of staying on the top of your data from wherever you are.

Soft benefits of making informed and timely decisions.

Client satisfaction.

production or testing turnaround time improvements.

gains of managing your team time off and vacations based on the projected individual and team workload and capacity.

many more......

We are here at APS to answer all your questions and concerns and do the practice with you to transfer your daily work experience from stress to confidence.

Comments